Quality Management

Quality Policy

As a member of the Sekisui Jushi Group, we contribute to the realization of a safe, secure, comfortable and sustainable society by providing products and services that meet customer trust and expectations.

- We prioritize communication with our customers and aim to provide products and services that prioritize customer satisfaction, taking into consideration safety and security as well as environmental impact.

- We strictly adhere to relevant laws and regulations related to our products and services, social norms, and internal rules to fulfill our responsibilities as a corporation.

- Never satisfied with the status quo, we continuously improve our quality management activities in pursuit of a richer society.

Quality Goal Setting

Under the Quality Policy, we set annual quality goals and quality plans to improve quality and create products that satisfy our customers. We also manage and follow up on implementation progress.

We have established a quality management system based on ISO9001 at all business sites and are continuing to maintain certification registration.

- Registered Certification Body

- Management System Assessment Center (MSA)

- Registration Number

- MSA-QS-937

- Certification Date

- February 15, 2001

- Valid Until

- February 14, 2028

- Applicable Standard

- JIS Q 9001:2015 (ISO 9001:2015)

- Registered Quality Management System

-

- Design and construction related to roadside facilities (signs, noise barriers, guardrails, tunnel interiors, road markings, etc.) and repair of civil structures.

- Design, development, manufacturing and sale of safety equipment, construction-related materials and machinery.

- Design, development, manufacturing and sale of road marking materials and pavement materials.

- Organizational Scope Covered by Registration

- Head Office, Hokkaido Branch, Tohoku Branch, Kanto Sales Department, Kita Kanto Sales Office, Yokohama Sales Office, Chubu Branch, West Japan Sales Department, Kansai Sales Office, Kyushu Sales Office, Kanagawa Sales Office, Chushikoku Sales Office, Nagasaki Sales Office

Main Initiatives

①Rigorous Audits for Quality Management and Assurance

To ensure proper quality management, in addition to internal audits, we conduct regular audits of business partners such as contract manufacturers and suppliers. We verify compliance with regulations through on-site inspections and document reviews. We strive to form partnerships that lead to improved quality by implementing improvements in accordance with the level of identified issues.

②Strengthening Traceability

At Nippon Liner, we monitor products in batches so that all information related to our products is connected.

By understanding data related to manufacturing processes and raw material quality, we track what process a product goes through before being released to the market. This helps prevent problems before they occur, and by continuously evaluating and improving, we strive to supply safe and reliable products.

Product Quality Evaluation and Improvement

In August 2025, Nippon Liner constructed the Technology Innovation Center in Tochigi Prefecture. We utilize the latest measurement testing equipment and test fields to develop new products and carry out performance evaluations.

We will continue to work on evaluating and improving quality so that we can provide customers with even safer and more reliable products.

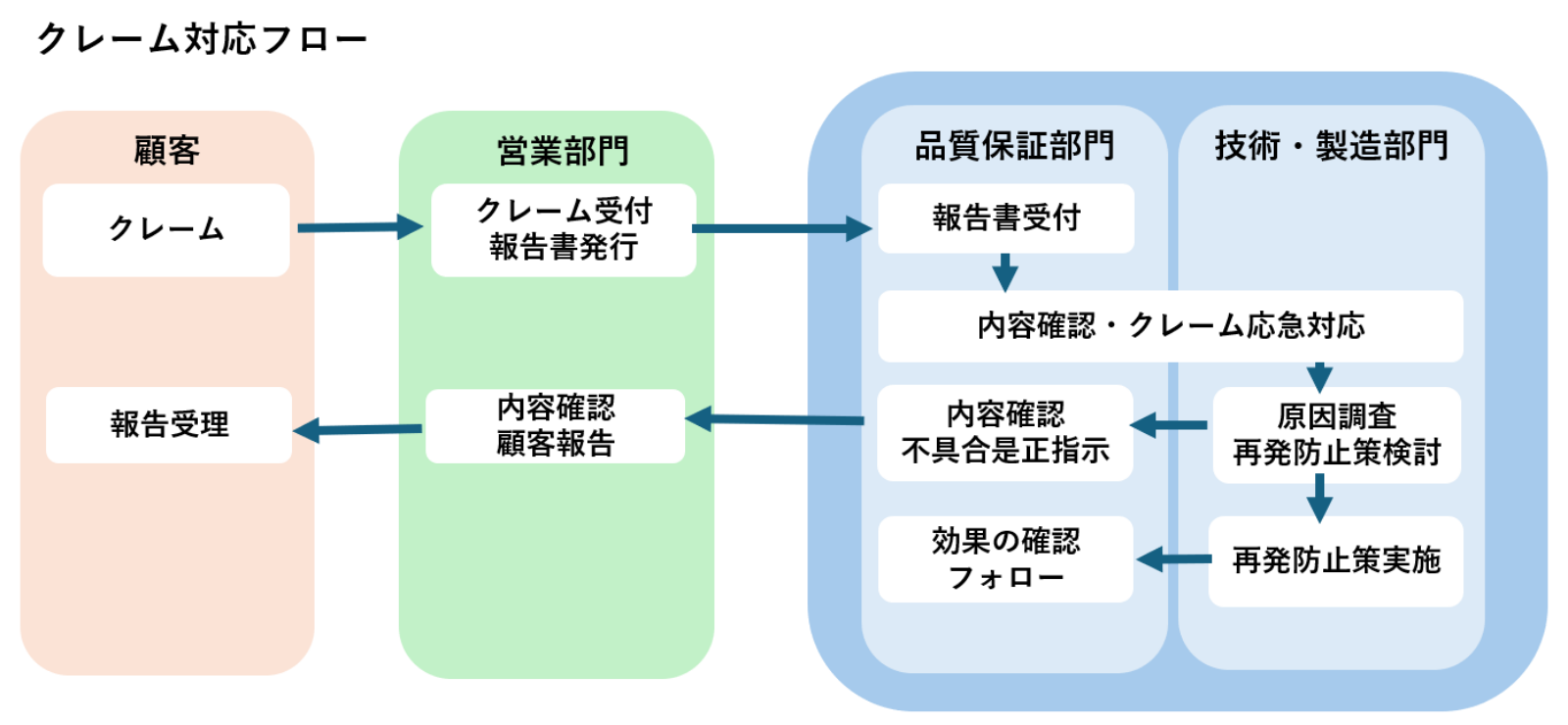

Complaint Handling and Prevention of Reoccurrence

When we receive a complaint from a customer, the sales department receives it, and then the quality assurance, manufacturing, and technical departments work together to investigate not only the specific complaint but also similar cases and implement preventive measures. After implementing countermeasures to prevent recurrence, we verify their effectiveness and the validity of the measures.